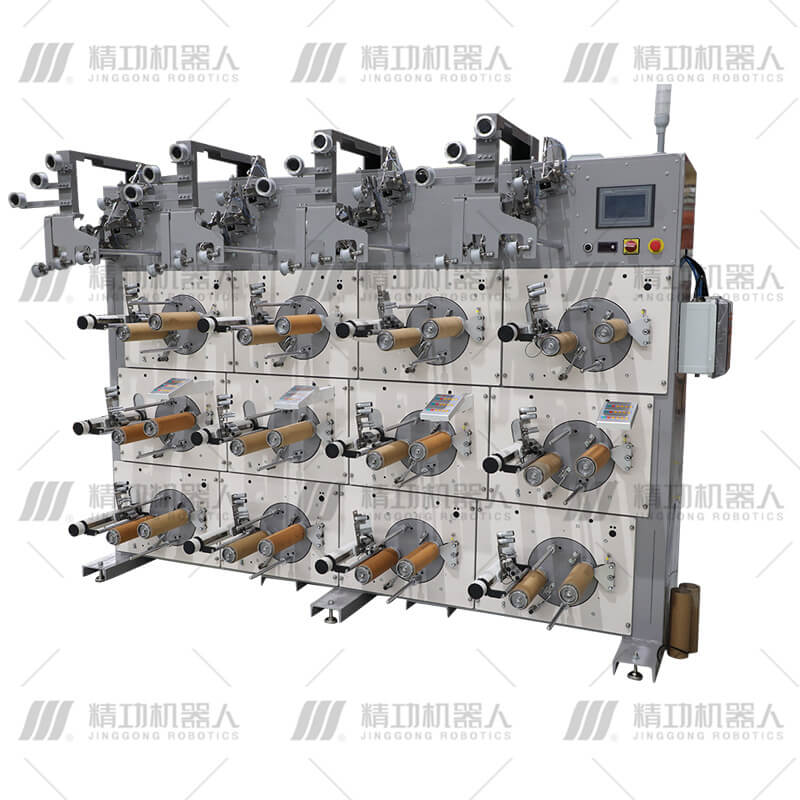

Cov pa roj carbon fiber winder

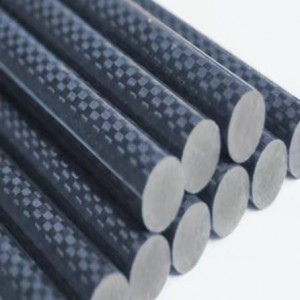

Kev piav qhia

Cov pa roj carbon fiber ntau yog ib hom tshiab ntawm lub zog siab thiab siab modulus fiber ntau nrog cov ntsiab lus ntawm cov pa roj carbon ntau dua 90%, uas muaj cov yam ntxwv ntawm lub teeb yuag, siab zog, corrosion tsis kam, siab modulus, tsis tshua muaj siab, tsis muaj creep, super kub tsis kam. -oxidizing ib puag ncig, zoo qaug zog tsis kam, zoo hluav taws xob thiab thermal conductivity, thiab lwm yam. Nws tsis yog tsuas yog muaj cov yam ntxwv ntawm cov khoom siv carbon, tab sis kuj muaj cov softness thiab processability ntawm textile fibers, thiab yog ib tiam tshiab ntawm reinforcing fibers.

Tech Specs

| del specification / technical parameters | Basic tsis muaj carbon hlau winder nrog siab tshaj winding muaj peev xwm ntawm 12kg

Cov tsis tseem ceeb ntawm carbon hlau winder nrog siab tshaj plaws winding muaj peev xwm ntawm 20kg

|

Qhov zoo

Lub ntsiab tseem ceeb Technology:

Main Innovation:

Product Video

FAQ

Q: Yog tias ib feem ntawm cov cuab yeej puas lawm, koj puas tuaj yeem muab cov khoom seem?

A: ua ntej qhov kev lees paub ntawm cov cuab yeej siv, peb lub tuam txhab tuaj yeem muab cov khoom seem sib xws dawb;Yog tias nyob rau hauv lub sijhawm lav, peb tuaj yeem pab cov neeg yuav khoom, yog tias tsim nyog, peb tuaj yeem yuav rau koj.

Q: Cov cuab yeej puas tuaj yeem ua kom ntseeg tau tias cov pa roj carbon fiber me me thiab tsis muaj kev pheej hmoo ntawm fiber ntau ntxeem tau thiab kev puas tsuaj thaum lub rooj cob qhia ntau lawm siv tau ntev?

A: txhua yam ntawm cov cuab yeej yog tsim thiab nruab nrog sealing muaj nuj nqi, uas tuaj yeem ua kom ntseeg tau tias cov pa roj carbon fiber tsis tuaj yeem cuam tshuam cov kev tswj hwm hauv lub txee, txhawm rau tiv thaiv cov khoom siv ntawm cov khoom siv.

Q: Cov cuab yeej puas muaj qhov kev nthuav dav ntxiv rau kev ntse ntse tsis siv neeg hlau txiav?

A: Cov khoom siv tuaj yeem muab cov teeb liab ntawm pneumatic pab xaim txo qis tom qab lub winding puv, thiab tuaj yeem cuam tshuam nrog cov khoom siv txuas ntxiv.

Kev ntsuas tus neeg siv

1. Cov khoom siv qis qis, kev ua haujlwm yooj yim, ruaj khov thiab txhim khu kev qha;

2. Kev teeb tsa thiab kev hloov kho ntawm cov cuab yeej siv tau nrawm heev, thiab cov lus teb tom qab muag cov chaw taws teeb tau zoo heev thaum muaj kev tsis ntseeg;

3. Tus qauv tsim yog tsim nyog thiab yooj yim rau kev khiav lag luam;

4. Cov khoom siv random tau ua tiav thiab cov ntaub ntawv random ntawm cov khoom siv yog qhov tseeb;

5. Cov txheej txheem winding yog qhov zoo, thiab qhov kawg ntawm lub ntsej muag tsim cov nyhuv tsis yog qis dua rau lub tshuab nqa tuaj!Winding txoj kab uas hla, gram hnyav thiab lwm yam winding tsis ua tau raws li qhov kev cia siab thiab kev lag luam qauv.

Khoom Qhia

| del specification / technical parameters | Basic tsis muaj carbon hlau winder nrog siab tshaj winding muaj peev xwm ntawm 12kg

Cov tsis tseem ceeb ntawm carbon hlau winder nrog siab tshaj plaws winding muaj peev xwm ntawm 20kg

|

lub ntsiab tseem ceeb technology:

1. Cov kev ntsuas winding tau teeb tsa kom raug thiab tsim nyog los xyuas kom meej tias lub ntsej muag kawg ntawm cov khoom zoo nkauj thiab tsis muaj plaub hau.

2. Lub reeling ceev yog qhov tseeb, thiab winding nro yog tswj kom tsim nyog.Tag nrho winding yog compact thiab puv.

3. Siv tag nrho cov nyiaj ntawm tib neeg-tshuab kev sib cuam tshuam, kom kev ua haujlwm yooj yim thiab cov qauv kos duab yog tsim nyog.

4. Kev nyeem ntawv tus kheej ntawm winding khiav yog qhov tseeb thiab qhov kev sib hloov ceev yog qhov tseeb thiab tsim nyog.

5. Qhov tseeb qhov tseem ceeb ntawm winding nro, winding ratio thiab lwm yam txheej txheem yuav tsum tau teem raws li qhov kev paub ntawm txawv K tus lej cab.

6. Cov qib kev tiv thaiv ntawm chav tsev tau txiav txim siab txog qhov tshwj xeeb ntawm cov pa roj carbon fiber ntau los xyuas kom meej tias cov khoom siv nws tus kheej raug kaw rau hauv qhov chaw thiab muaj kev sib pauv cua sov.

Lub ntsiab Innovation:

1. Lub tshuab txiav tshiab tsis siv neeg yog saws nyob rau hauv txoj haujlwm txiav, nrog kev txiav kev ua tiav siab, cov pob txha du thiab ruaj khov ua haujlwm.

2. Tus tshiab tsis siv neeg zawm mechanism yog saws nyob rau hauv lub nruj ib feem, nrog loj nro quab yuam thiab tsis muaj axial txav.

3. Tus tshiab nro tswj mechanism yog saws ntawm cov hlau lead, lub viav caj npab lub kaum sab xis tawm tswv yim yog qhov tseeb, thiab kev tswj nruj yog ruaj khov.

4. Lub tsev yog tsim thiab nruab nrog kev ywj pheej kov lub vijtsam thiab PLC, thiab kev sib cuam tshuam ntawm tib neeg-lub computer yog du.

5. Lub tshuab tshiab tsis siv neeg xaim thawb lub tshuab yog saws nyob rau hauv txoj hauj lwm pub mis, uas muaj lub zog thawb ntev, thiab tuaj yeem muab cov xaim thawb lub teeb liab tom qab thawb tawm, uas tuaj yeem ua tiav kev ua haujlwm tsis siv neeg ntawm cov ntawv raj hauv qab cov hlau thiab ntawm daim ntawv yeeb nkab nrog cov tom ntej manipulator.

Q: Yog tias ib feem ntawm cov cuab yeej puas lawm, koj puas tuaj yeem muab cov khoom seem?

A: ua ntej qhov kev lees paub ntawm cov cuab yeej siv, peb lub tuam txhab tuaj yeem muab cov khoom seem sib xws dawb;Yog tias nyob rau hauv lub sijhawm lav, peb tuaj yeem pab cov neeg yuav khoom, yog tias tsim nyog, peb tuaj yeem yuav rau koj.

Q: Cov cuab yeej puas tuaj yeem ua kom ntseeg tau tias cov pa roj carbon fiber me me thiab tsis muaj kev pheej hmoo ntawm fiber ntau ntxeem tau thiab kev puas tsuaj thaum lub rooj cob qhia ntau lawm siv tau ntev?

A: txhua yam ntawm cov cuab yeej yog tsim thiab nruab nrog sealing muaj nuj nqi, uas tuaj yeem ua kom ntseeg tau tias cov pa roj carbon fiber tsis tuaj yeem cuam tshuam cov kev tswj hwm hauv lub txee, txhawm rau tiv thaiv cov khoom siv ntawm cov khoom siv.

Q: Cov cuab yeej puas muaj qhov kev nthuav dav ntxiv rau kev ntse ntse tsis siv neeg hlau txiav?

A: Cov khoom siv tuaj yeem muab cov teeb liab ntawm pneumatic pab xaim txo qis tom qab lub winding puv, thiab tuaj yeem cuam tshuam nrog cov khoom siv txuas ntxiv.

1. Cov khoom siv qis qis, kev ua haujlwm yooj yim, ruaj khov thiab txhim khu kev qha;

2. Kev teeb tsa thiab kev hloov kho ntawm cov cuab yeej siv tau nrawm heev, thiab cov lus teb tom qab muag cov chaw taws teeb tau zoo heev thaum muaj kev tsis ntseeg;

3. Tus qauv tsim yog tsim nyog thiab yooj yim rau kev khiav lag luam;

4. Cov khoom siv random tau ua tiav thiab cov ntaub ntawv random ntawm cov khoom siv yog qhov tseeb;

5. Cov txheej txheem winding yog qhov zoo, thiab qhov kawg ntawm lub ntsej muag tsim cov nyhuv tsis yog qis dua rau lub tshuab nqa tuaj!Winding txoj kab uas hla, gram hnyav thiab lwm yam winding tsis ua tau raws li qhov kev cia siab thiab kev lag luam qauv.