Carbon Fiber Precursor Ntau Lawm Kab

Kev piav qhia

Cov pa roj carbon fiber ntau cov txheej txheem ua ntej uas tau txais Dimethyl Sulfoxide (DMSO) ua cov kuab tshuaj, Acrylonitrile (AN) ua thawj monomer, Itaconic Acid ua tus thib ob monomer, AIBN ua tus pib muaj binary copolymerization, thiab lub dav hlau ntub dej spinning. yog qhov kev xaiv sab saum toj pom zoo ntawm cov kws tshaj lij carbon fiber.

Tech Specs:

| Tsis muaj. | Yam khoom | Chav tsev | Specifications | Lus hais |

| 1 | Linear Ceev | dtex ua | 1.15 | |

| 2 | Tensile zog | CN/dtex | ≥4.0 | |

| 3 | Elongation | % | 12 ± 2 | |

| 4 | Dimethyl Sulfoxide (DMSO) Cov ntsiab lus | % | 0.03 | |

| 5 | Cov ntsiab lus roj | % | 0.5-0.1 hli | |

| 6 | Kawg Breakage Rate | % | <3 | |

| 7 | Moisture Regain | % | ≤1 | |

| 8 | Qhov tshwm sim | Tsis Pom Tsis Pom Tsis Pom Kev Filament |

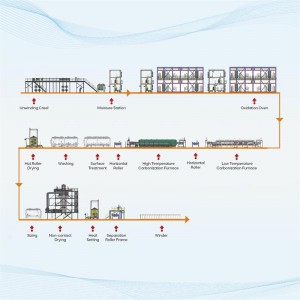

Txheej txheem:

Raw Material Preparation —→ Monomer Mixture —→ Copolymerization —→ Primary Filtration —→ Monomer Removal —→ Secondary Filtration —→ Mixed Batch Neutralization —→ Tertiary Filtration —→ Cia —→ Defoam —→ Spinning —→ spin da dej (Primary) —→ spinning da dej (Secondary) —→ spin da dej (Tertiary) —→ huv —→ Kub Stretching —→ Oiling —→ ziab —→ Chav Stretching —→ Thaum tshav kub kub —→ Antistatic Treatment —→ Precursor Winding

| Tsis muaj. | Yam khoom | Chav tsev | Specifications | Lus hais |

| 1 | Linear Ceev | dtex ua | 1.15 | |

| 2 | Tensile zog | CN/dtex | ≥4.0 | |

| 3 | Elongation | % | 12 ± 2 | |

| 4 | Dimethyl Sulfoxide (DMSO) Cov ntsiab lus | % | <0.03 ib | |

| 5 | Cov ntsiab lus roj | % | 0.5-0.1 hli | |

| 6 | Kawg Breakage Rate | % | <3 | |

| 7 | Moisture Regain | % | ≤1 | |

| 8 | Qhov tshwm sim | Tsis Pom Tsis Pom Tsis Pom Kev Filament |

Raw Material Preparation —→ Monomer Mixture —→ Copolymerization —→ Primary Filtration —→ Monomer Removal —→ Secondary Filtration —→ Mixed Batch Neutralization —→ Tertiary Filtration —→ Cia —→ Defoam —→ Spinning —→ Spinning (Primary) —→ spin da dej (Secondary) —→ spin da dej (Tertiary) —→ huv —→ Kub Stretching —→ Oiling —→ ziab —→ Chav Stretching —→ Thaum tshav kub kub —→ Antistatic Treatment —→ Precursor Winding